What is this material that combines the characteristics of paper and stone? A novel material with potential applications across diverse fields.

This material, composed of a paper-like matrix reinforced with mineral components, exhibits a unique blend of properties. It combines the flexibility and lightweight nature of paper with the durability and strength of stone. Examples might include a paper-based building material resistant to weathering or a lightweight, strong packaging material. The specific composition would determine the precise balance of these properties.

The potential benefits of this material are substantial. Its lightweight nature could reduce transportation costs and environmental impact in various industries. Its enhanced durability compared to standard paper could extend product lifespan and reduce waste. Applications in construction, packaging, and even art and design are conceivable, offering possibilities for innovation and sustainability. Research into the material's creation, production, and application is likely to continue developing over time.

The exploration of this novel material presents opportunities for progress across numerous sectors. Further investigation into its properties, potential applications, and scalability is warranted.

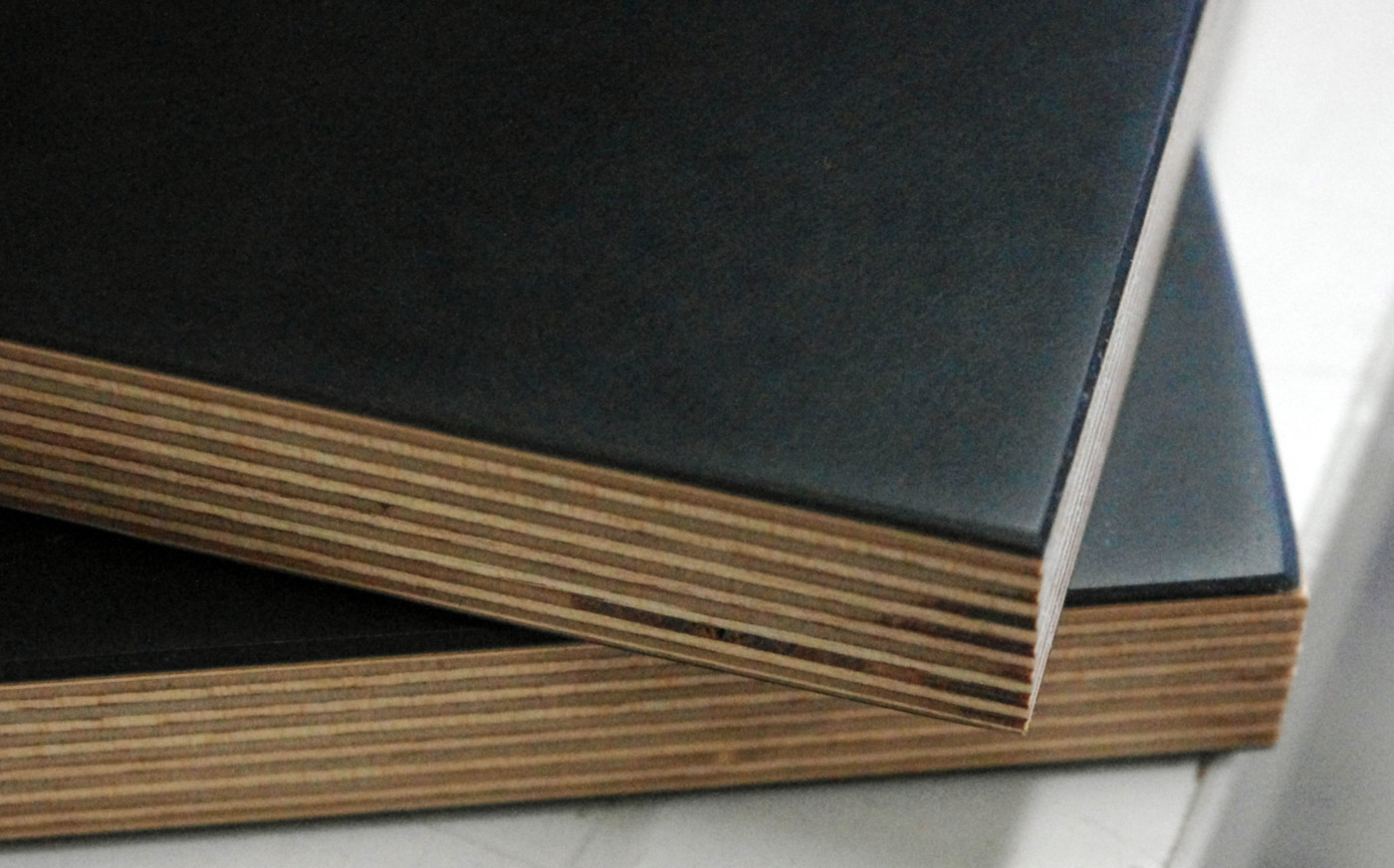

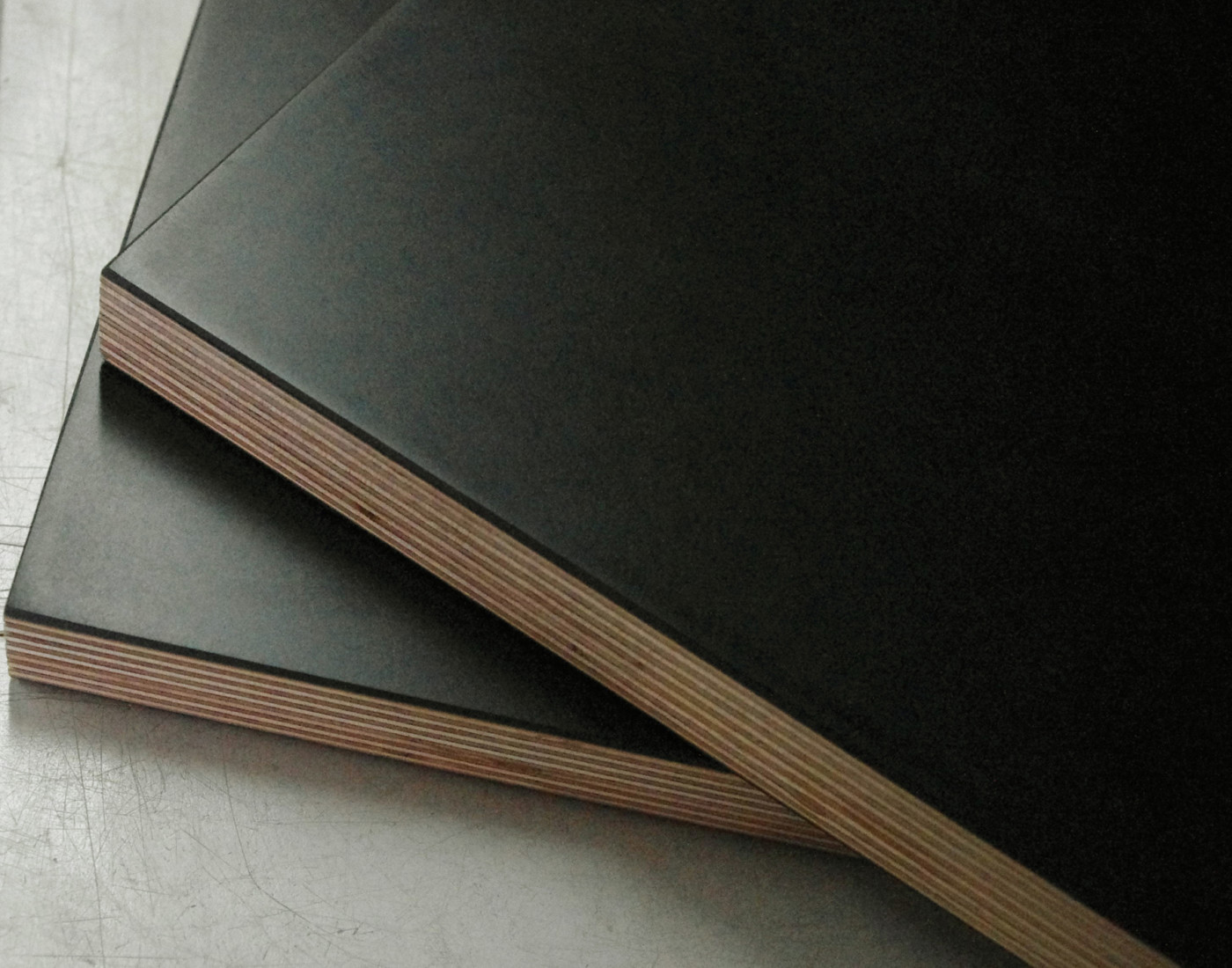

Paperstone

Understanding the multifaceted nature of "paperstone" requires examining its key characteristics and applications. This material's unique composition blends attributes of both paper and stone.

- Durability

- Lightweight

- Strength

- Flexibility

- Composition

- Sustainability

- Manufacturing

- Applications

The material's durability and strength, derived from mineral reinforcement, suggest applications in construction. Lightweight properties enable transport and reduce environmental impact. Flexibility allows for diverse shaping, from packaging to artistic forms. The exact composition is key to optimizing its properties. Sustainability is crucial; the material's production must be environmentally responsible. Manufacturing processes need to be efficient and minimize waste. Applications range from building materials to innovative packaging solutions, demonstrating potential across various sectors. This novel material's development combines the strengths of both paper and stone, potentially revolutionizing numerous industries.

1. Durability

Durability is a critical component of paperstone's potential applications. The material's ability to withstand environmental stresses, mechanical forces, and prolonged use determines its suitability for various tasks. A robust structure, resistant to degradation over time, is essential for long-term performance. This durability stems from the integration of mineral components within a paper-like matrix. The specific composition, particularly the proportion of minerals used, directly impacts the material's resistance to wear, tear, and weathering. For example, a paperstone product designed for outdoor use would require a higher mineral content to withstand exposure to rain, sun, and temperature fluctuations. Conversely, a paperstone intended for interior applications might exhibit acceptable durability with a lower mineral content.

The practical significance of understanding durability in paperstone is substantial. In construction, a durable paperstone material could contribute to long-lasting structures, potentially reducing maintenance and replacement costs. In packaging, the ability to endure transport and handling stresses is paramount. Durability is a key driver in ensuring product safety and reducing waste. Understanding the relationship between composition and durability enables designers and manufacturers to tailor paperstone to specific needs, maximizing its effectiveness across diverse applications.

In conclusion, durability is paramount for paperstone's successful implementation. The balance between the paper-like matrix and mineral reinforcement dictates the material's resilience. Optimization of this balance is crucial for targeted applications. Further research should explore the longevity of paperstone under different environmental conditions and operational stresses to validate its suitability for various end uses. Thorough examination of long-term performance metrics is vital for this material to realize its full potential across diverse sectors.

2. Lightweight

Lightweight construction materials offer significant advantages in various sectors. Paperstone, a material with a unique composite structure, inherits this benefit. The paper-like matrix, combined with strategically incorporated mineral components, contributes to reduced weight while retaining desired structural properties. This characteristic, a consequence of the material's composition, is crucial in applications demanding portability, ease of transport, or reduced environmental impact. Consider, for example, the advantages of a lightweight building material in architectural designs, enabling the construction of taller structures or the transportation of large-scale components. This also applies in the realm of packaging, where reduced weight translates to decreased fuel consumption during distribution and reduced material costs.

The practical implications of lightweight paperstone extend to numerous applications. In the construction industry, reduced weight can lessen the strain on supporting infrastructure. This, in turn, can potentially lower material costs and improve sustainability. In transportation, lighter packaging leads to lower fuel consumption, decreasing emissions and transport costs. The material's lightweight nature, a fundamental property resulting from its unique composition, opens opportunities for innovative design solutions. The reduction in weight contributes to increased maneuverability, affordability, and efficiency in various sectors, including building construction, packaging, and transportation. Consequently, understanding and optimizing this property is crucial for paperstone's success in various sectors.

Lightweight properties are essential to paperstone's viability across diverse applications. While the balance between strength, durability, and weight is key, the potential for substantial reductions in material and operational costs related to lightweight construction warrants further investigation. The incorporation of advanced material science principles into the production of paperstone may further optimize this feature. Understanding the interplay of weight reduction and material properties is essential to unlocking the true potential of paperstone across multiple fields, from infrastructure development to sustainable packaging solutions.

3. Strength

Strength, a critical property in any material, assumes particular importance in the context of paperstone. The material's ability to withstand applied forces and stresses directly influences its suitability for diverse applications. Understanding the factors contributing to paperstone's strength is essential for evaluating its potential.

- Mineral Reinforcement

The incorporation of mineral components into a paper-like matrix significantly enhances strength. Minerals, with their inherent rigidity, act as reinforcements, distributing stress more effectively than a pure paper material. This reinforcement is analogous to the way steel rods strengthen concrete. The specific type and quantity of mineral incorporated directly influence the material's ultimate tensile strength and resistance to compression.

- Fiber Orientation and Arrangement

The alignment and arrangement of fibers within the paper-like matrix also play a significant role. A structured, organized arrangement of fibers offers more resistance to deformation compared to a random arrangement. This internal structure, a defining element of paperstone, directly impacts the material's ability to withstand bending, shearing, and other mechanical stresses. The processing techniques employed in producing paperstone likely influence the fiber orientation, thus impacting the material's strength characteristics.

- Manufacturing Techniques

The manufacturing methods employed to create paperstone products significantly impact the material's strength. Optimizing techniques like pressure application, curing procedures, and drying conditions can create a dense and homogeneous structure, enhancing its overall strength. Proper control over these parameters is critical for ensuring a consistent level of strength across different products or batches. The intricate process of bonding the mineral components to the paper matrix influences the overall strength.

- Structural Integrity

The structural integrity of paperstone is directly related to its strength. Flawed or inconsistent material structures, from improper mixing of components to internal voids, will invariably reduce the material's strength. Quality control measures are crucial throughout the manufacturing process to ensure the desired strength attributes are consistently achieved. A strong, uniform structure is paramount for applications demanding high levels of mechanical resilience.

The strength of paperstone is not a single, isolated property but rather a complex interplay of these factors. A comprehensive understanding of mineral reinforcement, fiber orientation, manufacturing techniques, and structural integrity is crucial for optimizing the material's strength for specific applications. Future research should focus on tailoring these factors for optimized strength properties relevant to various potential uses, such as construction, packaging, and even artistic endeavors. The strength potential inherent in this material is significant, and its development depends on a thorough understanding of these key contributing factors.

4. Flexibility

The flexibility of paperstone, a composite material, is a crucial characteristic influencing its adaptability and suitability for diverse applications. Understanding its degree of flexibility, alongside its inherent strength and durability, is essential to evaluating its potential for use in various sectors. The balance between flexibility and rigidity is a significant design consideration.

- Impact of Matrix Material

The paper-like matrix within paperstone forms the foundation for its flexibility. The inherent properties of this matrix, such as fiber alignment and intermolecular bonding, significantly determine the material's pliability and ability to deform without fracturing. The nature of the cellulose or other fiber components directly influences the range of bendable forms achievable. Variations in fiber types and processing techniques will directly affect the flexural behavior.

- Influence of Mineral Reinforcement

Mineral reinforcement, while enhancing strength, can also influence the flexibility of paperstone. The quantity and type of mineral components integrated into the matrix will impact the material's overall stiffness. Higher concentrations of stiff minerals can lead to reduced flexibility, while a strategic distribution can create a more balanced composite with desirable properties. The precise interplay between these components dictates the material's overall flexibility.

- Application-Specific Requirements

Flexibility requirements differ drastically depending on the application. For instance, packaging applications might demand a certain degree of flexibility for shaping and ease of handling. Construction or architectural applications, conversely, might prioritize rigidity over flexibility. Understanding the specific bending and deformation needs for each use case is essential to tailor the material accordingly. Product designers must consider the desired flexibility in relation to the material's other key attributes, such as durability and strength.

- Manufacturing Process Considerations

The manufacturing process significantly impacts the flexibility of the resulting paperstone material. Variables in the mixing and processing stages influence the homogeneity of the matrix and its impact on flexibility. Control over processing parameters is crucial to ensure a consistent, predictable level of flexibility across different productions. These considerations dictate the optimal production methods for achieving desired levels of flexibility.

In summary, the flexibility of paperstone is not a monolithic property but rather a result of the interaction between the paper-like matrix and the mineral reinforcement, along with manufacturing choices. Optimizing the material's flexibility is crucial to maximizing its utility in diverse applications. The delicate balance between strength, durability, and flexibility determines the material's ultimate suitability for specific use cases. Further investigation into the specific material properties, production parameters, and application-driven needs is paramount for a detailed understanding of the material's full potential.

5. Composition

The composition of paperstone is fundamental to its properties and applications. The specific materials comprising the paper-like matrix and the mineral reinforcement directly influence the material's strength, durability, flexibility, and overall performance. A precise understanding of these components is crucial for achieving desired outcomes in various applications. For example, a higher proportion of stronger minerals like quartz might enhance durability but reduce flexibility, while a lower proportion might yield a more flexible material but with reduced strength. The exact blend dictates the material's ultimate suitability.

The choice of minerals significantly affects paperstone's properties. Different minerals possess varying densities, hardness, and chemical resistance. The combination of these factors directly impacts the material's weight, resistance to degradation, and overall suitability for different environments. The use of lightweight minerals might reduce the material's weight and enhance transportability, but it might also compromise its strength. The selection of the matrix material is also pivotal. The type of fibers, cellulose sources, and processing methods influence the material's flexibility, absorbency, and overall structural integrity. The composition's relationship to the targeted application is keyfor instance, a construction application demands different material ratios than a packaging application. Examples of potential compositions could include blends of cellulose fibers, clay minerals, calcium carbonate, and quartz, each contributing unique properties.

In conclusion, the composition of paperstone directly dictates its performance characteristics. A nuanced understanding of the interplay between mineral reinforcement and the matrix materials is essential for optimizing the material for specific applications. Further research into innovative compositions could unlock new possibilities in various sectors. The potential for tailor-made compositions, meticulously balancing different materials for desired properties, demonstrates a dynamic area of advancement. This comprehensive approach to composition is vital for widespread adoption of paperstone technology. Careful consideration of the cause-and-effect relationships within the material's composition is vital to its successful implementation across numerous fields.

6. Sustainability

The environmental impact of materials is a critical consideration in modern manufacturing. Paperstone, with its composite nature, presents both opportunities and challenges in this regard. Sustainability, as a component of paperstone's development, hinges on responsible sourcing of materials, efficient manufacturing processes, and consideration for the product's lifecycle. The ecological footprint of raw materials and the energy demands of processing heavily influence the material's overall sustainability rating. Recycling and reuse potential are critical factors. If the raw materials are sustainably harvested, and if the manufacturing process minimizes waste and energy consumption, paperstone can offer a more environmentally friendly alternative to conventional materials. For example, utilizing recycled paper fibers in the matrix reduces reliance on virgin wood pulp, lowering deforestation impact.

Practical applications of paperstone, focusing on sustainability, can encompass construction, packaging, and even art. In construction, a lightweight, durable paperstone material could reduce the energy required for transportation and potentially decrease the embodied energy of buildings. Sustainable packaging derived from paperstone could decrease reliance on petroleum-based plastics, minimizing waste streams and the environmental damage associated with plastic production and disposal. In the arts, the material could offer a more environmentally conscious alternative to traditional materials if produced responsibly. The key lies in balancing the material's desirable properties with sustainable production methods. Quantifiable metrics for assessing sustainability, like embodied energy calculations and carbon footprint analysis, are crucial for proper evaluation.

Understanding the link between paperstone and sustainability underscores the importance of holistic material assessments. Sustainable manufacturing practices, material sourcing, and end-of-life considerations are crucial components. Challenges remain, such as optimizing manufacturing processes to minimize environmental impact. Ultimately, success in applying paperstone depends on its integration into environmentally conscious design and production methods. Ongoing research and development focusing on responsible resource management will guide the material's growth and acceptance. The environmental benefits of paperstone become clear when considered within the broader context of its lifecycle assessment, encompassing material sourcing, manufacturing processes, and end-of-life management, including potential recyclability. Achieving a truly sustainable paperstone hinges on meticulously considering the entire process.

7. Manufacturing

Manufacturing processes significantly impact paperstone's properties and applications. The methods employed directly influence the material's characteristics, from its final strength and durability to its overall structural integrity. Consideration of specific manufacturing steps is essential for achieving desired outcomes and controlling variability. The quality control measures integral to each step directly affect the material's performance in various applications. Optimal manufacturing procedures minimize defects and ensure consistent properties.

Specific manufacturing techniques for paperstone encompass the mixing of mineral components with the paper-like matrix, the application of pressure during formation, and the subsequent drying or curing processes. Variations in these stages impact the final product's physical characteristics. For instance, variations in pressure application could lead to inconsistent density, affecting strength and durability. The uniformity of mineral distribution across the material dictates the evenness of the reinforced structure. Control over these variables is essential for achieving reproducible results. Furthermore, manufacturing protocols influence the material's surface finish, further impacting its aesthetic appeal and potential applications. Examples include specialized machinery for layering components and precise temperature control during curing, all playing critical roles in determining final properties.

Understanding the intricate connection between manufacturing and paperstone's characteristics is vital for ensuring consistency, quality, and cost-effectiveness. Successful commercialization hinges on the establishment of robust, scalable manufacturing processes. Optimization of these processes minimizes waste, lowers production costs, and ensures a consistent level of material quality. Real-world examples demonstrate that the development of efficient manufacturing procedures is critical to widespread adoption and commercial viability. Improvements in manufacturing techniques can lead to enhanced material properties, and this allows for broader applications. Further research and development into innovative manufacturing methods are crucial for unlocking the material's full potential in diverse sectors.

8. Applications

The potential applications of paperstone are numerous and diverse, stemming from its unique combination of properties. The material's strength, durability, lightweight nature, and flexibility influence its suitability for various sectors. Real-world examples illustrate how these properties enable innovative solutions in areas such as construction, packaging, and design. The success of paperstone hinges on understanding and leveraging these diverse application possibilities.

Specific applications benefit from distinct characteristics of paperstone. In construction, the lightweight nature of the material, combined with its strength, can reduce the weight of structural elements, minimizing load on foundations and enabling taller structures. In packaging, its durability and adaptability to various shapes and sizes make it suitable for protecting products during transit, offering an alternative to traditional materials. Its flexibility lends itself to creative design and unique product formations. The potential for innovative applications in the field of artistic design is also promising, offering unique possibilities for artistic expression and form. Successful implementation hinges on tailoring the material's properties to the specific requirements of each application. For instance, the composition might be adjusted to optimize durability for construction or flexibility for artistic endeavors. Such adaptability underscores the versatility of paperstone.

The significance of applications lies in the material's practical utility. Successful implementation necessitates a deep understanding of the specific properties required for each application. The interplay between the material's composition, its manufacturing process, and the intended use dictates its performance. Further research and development are vital to refining the material's properties and widening its applicability. Addressing challenges such as cost-effectiveness and scalability will be crucial for broader acceptance and utilization. Understanding the varied applications unlocks the full potential of paperstone and propels its advancement across various industries.

Frequently Asked Questions about Paperstone

This section addresses common inquiries regarding paperstone, a novel composite material. Clear and concise answers are provided to foster a comprehensive understanding.

Question 1: What is paperstone, exactly?

Paperstone is a composite material combining the flexibility and lightweight nature of paper with the durability and strength of stone. Its composition typically involves a paper-like matrix reinforced with mineral components, leading to a unique blend of properties. The specific mineral composition determines the material's final characteristics.

Question 2: What are the primary benefits of using paperstone?

Key benefits include enhanced durability compared to traditional paper, reduced weight for easier transportation and handling, and potential for environmental sustainability through responsible material sourcing and manufacturing. The material's adaptability to diverse forms allows for applications ranging from construction to packaging.

Question 3: How does the mineral reinforcement affect paperstone's strength and durability?

Mineral reinforcement acts as a structural support system within the paper matrix. The type and concentration of minerals directly impact the material's tensile strength, resistance to compression, and overall durability. This reinforcement improves the material's ability to withstand various stresses.

Question 4: What are the potential applications of paperstone?

Potential applications span diverse sectors. In construction, its lightweight nature and structural strength make it a possible alternative to traditional materials. In packaging, the durability and shaping possibilities present potential for innovative designs. Further applications are emerging in areas like art and design, owing to the material's adaptability.

Question 5: What are the current challenges in developing and implementing paperstone?

Challenges include optimizing manufacturing processes for cost-effectiveness and scalability. Developing standardized testing methods to ensure consistent material properties across different production runs is necessary. Further research is required to explore and address potential long-term environmental impacts throughout the entire material lifecycle.

Understanding paperstone's properties, benefits, and challenges is crucial for its successful integration into various industries. Continued research and development are expected to drive advancements and broaden its applications.

The following sections delve deeper into specific aspects of paperstone technology, including manufacturing, sustainability, and potential applications.

Conclusion

This exploration of paperstone reveals a composite material with multifaceted potential. Its combination of paper's flexibility and stone's durability offers innovative applications across various sectors. Key properties, such as lightweight construction, enhanced strength, and potential for sustainable manufacturing, highlight promising avenues for development. The intricate relationship between composition, manufacturing, and application is central to understanding and optimizing the material for diverse use cases. Further research and development into the material's lifecycle, including sustainable sourcing and disposal, are essential.

The future of paperstone hinges on addressing challenges related to cost-effectiveness and scalability. Optimizing manufacturing processes and establishing robust quality control protocols are essential steps for widespread adoption. Further research into the long-term performance of the material under diverse environmental conditions is crucial for validating its applications. Ultimately, the success of paperstone depends on its ability to meet the demands of modern industries while contributing to environmentally responsible practices. Continued innovation and meticulous evaluation are critical for realizing the full potential of this promising composite material.